Handcrafted in the Sonoran Desert

Making chocolate is a difficult task to begin with and making chocolate in the desert is quite the undertaking. However, we believe that anything worth doing should be a challenge.

The chocolate we make is truly a collaboration with the farm workers who grow, harvest, ferment, and dry the cacao. Our goal is to honor their hard work by processing the cacao as minimally as possible to reveal the beautiful and complex flavors inherent in the beans.

Transparent Sourcing

Costa Esmeraldas

Esmeraldas, Ecuador

Costa Esmeraldas is a family-owned, single estate farm that is operated entirely by the Salazar family. Located in the Esmeraldas province of Ecuador, a region not traditionally known for fine flavor cacao, the farm has reclaimed land once occupied by cattle pastures. The Salazars have decades of expertise in mineral exploration, environmental remediation, and also operate Fundación Salazar, an independent non-profit that operates with the mission to create lasting benefits from communities nearby resource extraction operations.

Latitude Trade Co.

Bundibugyo, Uganda

Latitude Trade Company is an Ugandan registered social enterprise owned and managed by Jeff Steinberg. The company purchases wet cacao from over 1000 organic small holder farmers in several communities in the district of Bundibugyo, 52% of whom are women. In the village of Bumate, LTC operates a centralized fermentation facility and warehouse. Not only does the company produce fine flavor cocoa for export, they also manufacture award winning chocolate in Kampala under the brand name Latitude Craft Chocolate.

Kokoa Kamili

Kilombero Valley, Tanzania

Kokoa Kamili was founded by Brian LoBue and Simran Bindra, in the Kilombero Valley of Tanzania. The company operates a central fermentary that works with nearly 3000 small shareholder farms. In an area that has historically received some of the lowest prices for cocoa in the country, Kokoa Kamili is now paying a premium well above market rate to the farmers for wet cacao, and controlling the post-harvest processing themselves. This results in higher compensation and a reduced workload for the farmers, and ultimately produces a more consistent, high quality product.

Bejofo Estate

Sambirano Valley, Madagascar

Bejofo Estate is an organic cacao orchard that is part of the larger Akesson Estate in northwest Madagascar’s Sambirano valley. Managed by Bertil Akesson, who has specialized in growing fine cocoa, pepper, and other spices for many years, Bejofo Estate produces 300 tons of cocoa a year. The cocoa has been designated as certified “Heirloom” by the Heirloom Cacao Preservation Initiative (HCP).

Maya Mountain

Toledo, Belize

Maya Mountain Cacao was founded in 2010 and has helped put Belize on the craft chocolate map as a pioneer in the centralized fermentery social enterprise model. It is the first exporter in the country to manufacture high-quality, centrally-fermented cacao for the U.S. craft chocolate market. In the Toledo and South Stann Creek regions, MMC works with 350+ certified organic smallholder cacao farming families, the majority of which are indigenous Q’eqchi’ and Mopan Maya who have been growing cacao for generations. MMC was awarded an Heirloom Cacao Preservation (HCP) designation in 2014, and is committed to being a long-term, sustainable, and transparent company.

Hacienda Tranquilidad

Itenez, Bolivia

Hacienda Tranquilidad, a farm producing both wildcrafted and single-estate cacao, is located on 1,500 acres deep in the Bolivian Amazon Basin. Volker Lehmann, the estate's owner, was the first person in the modern age to commercialize the endemic Beniano cacao variety. The massive wild or "Silvestre" cocoa trees grow in an 850-acre natural forest, where they are left alone each year until harvest. These tiny beans have been designated as certified “Heirloom” by the Heirloom Cacao Preservation Initiative (HCP).

Our Process

We craft chocolate in small batches at our factory in the historic Santa Rita Park neighborhood of Tucson, Arizona, using cocoa beans from all over the world. The process of making fine flavor chocolate starts long before the cocoa beans reach our factory.

On the Farm

-

01

Grow

Theobroma Cacao grows between the tropics of Cancer and Capricorn.

-

02

Grow

Tiny flowers develop into seed pods that grow from the limbs and trunks of the trees.

-

03

Harvest

Seed pods are selected by hand at peak ripeness, cut from the tree, and collected.

-

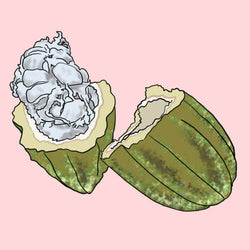

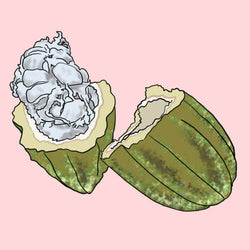

04

Harvest

Pods are cracked open and the inner fruit and seeds are removed.

-

05

Ferment

Wooden boxes are filled with the wet cacao seeds and are covered with banana leaves or burlap, where they will go through a process of fermentation for about 3-8 days.

-

06

Dry

Boxes are emptied and the seeds are spread out on raised beds to dry in the sun for about 5-7 days. After drying, the seeds – now referred to as cocoa beans – are ready to be bagged and exported.

-

FYI

Fermentation and drying are some of the most important steps in flavor development

-

07

Transport

Bags of cocoa are loaded into shipping containers which are transported on large boats that travel to ports all over the world.

In Our Factory

-

01

Sort

Once the cocoa beans arrive in our factory, the very first thing we do is hand sort them, removing debris and beans that do not meet our standards.

-

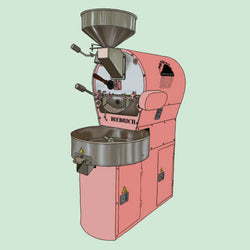

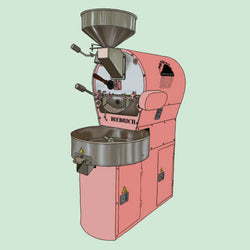

02

Roast

We develop specific roast profiles that enhance the natural flavors in each cocoa bean origin.

-

FYI

Aside from fermentation and drying, the best opportunity to influence flavor is in roasting

-

03

Winnow

Cocoa beans have a paperlike husk surrounding the nib that needs to be removed after roasting

-

04

Winnow

Beans are crushed and the mixture of husk and nib is separated through a combination of gravity and vacuum force.

-

05

Refine

Cocoa nibs are stone-ground along with sugar (and milk powder, if we are making milk chocolate) over the course of 72–96 hours in a machine called a melanger.

-

06

Conch

The liquid chocolate is agitated and aerated, improving mouthfeel and flavor

-

07

Sieve

The finished chocolate is poured out into large metal containers and allowed to cool.

-

08

Age

Solid blocks of chocolate are aged for a minimum of 30 days in cellar conditions.

-

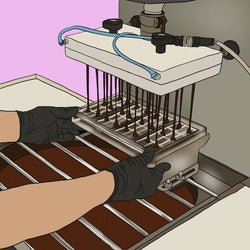

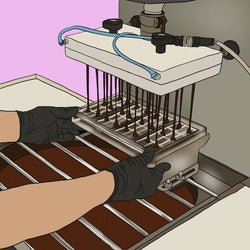

09

Temper

Solid blocks of chocolate are melted and taken through a process of heating and cooling known as tempering. Chocolate is deposited into polycarbonate molds.

-

10

Mold

Chocolate is deposited into polycarbonate molds which are placed onto a cooling rack to crystallize for and hour or so.

-

11

Package

Finished chocolate bars are turned out of their molds and packaged by hand.